Poly Aluminum Chloride for Drinking Water Treatment

I.Introduction: Name: Poly Aluminum Chloride (PAC) for Drinking Water Treatment Technical Standard: GB15892-2020

II.Product Characteristics: This product has fast dissolution speed, non-corrosiveness, wide adaptability to water quality, and excellent effects in turbidity removal, decolorization, and odor removal. It requires less dosage during coagulation, as coagulant, forms large and fast-settling flocs, and the purified water quality completely meets the corresponding standard requirements. It has low insoluble matter, low basicity, and low iron content. It is easily soluble in water, and purification is efficient and stable.

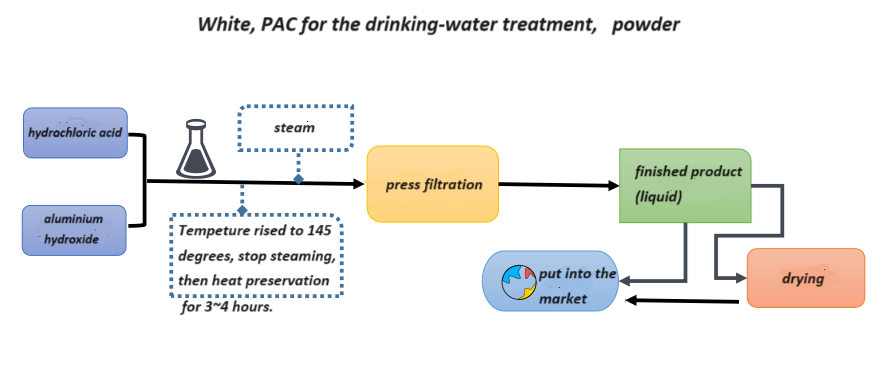

III.Production Process: Spray Drying: Liquid Raw Material → Pressure Filtration → Spray Tower Spraying and Drying → Finished Product Raw Materials: Aluminum Hydroxide + Hydrochloric Acid

IV.Different Synthetic Costs: Due to the stable performance, wide adaptability to water bodies, fast hydrolysis speed, strong adsorption capacity, formation of large flocs, quick settling, low effluent turbidity, and good dewatering performance of spray-dried products, the dosage of spray-dried products is reduced compared to drum-dried products under the same water quality conditions. Especially in poor water quality conditions, the dosage of spray-dried products can be halved compared to drum-dried products, not only reducing the labor intensity of workers but also reducing the water production cost for users.

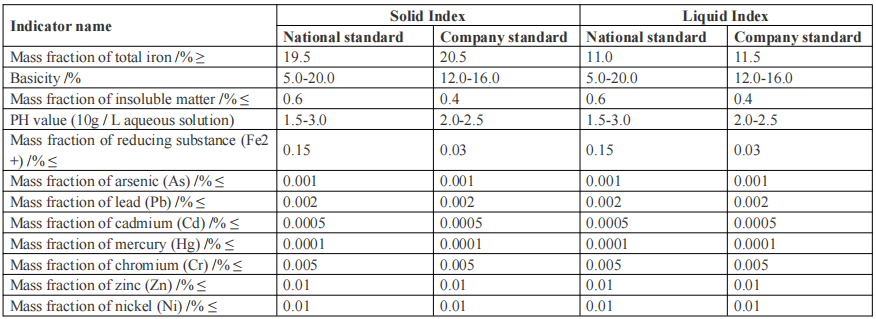

V.Main Technical Indicators: Aluminum Oxide: During the spray drying process, the centrifuge uniformly sprays the mother liquor into the drying tower, making the aluminum oxide content uniform, stable, and easily controllable within the specified range. It enhances the adsorption capacity of particles and achieves both coagulation and flocculation effects, which other drying methods cannot achieve. Basicity: During water treatment, the basicity directly affects the water purification effect. We use a centrifugal spray drying method to increase the product's basicity while maintaining the original activity of the mother liquor. Meanwhile, the basicity can be adjusted according to different water qualities. Drum drying is prone to damage the basicity, with a small range of product basicity and narrow adaptability to water quality. Insoluble Matter: The level of insoluble matter affects the comprehensive water purification effect and increases the utilization rate of chemicals, resulting in a significant comprehensive effect.

VI.Applications: Poly Aluminum Chloride is an inorganic polymer coagulant. Through the action of hydroxyl ions functional groups and multivalent anions polymerization functional groups, it produces inorganic polymers with large molecular weight and high charge.

1.It can be used for the treatment of river water, lake water, and groundwater.

2.It can be used for industrial water and industrial circulating water treatment.

3.It can be used for wastewater treatment.

4.It can be used for the recovery of coal mine flushing wastewater and ceramic industry wastewater.

5.It can be used for the treatment of wastewater containing fluorine, oil, heavy metals in printing factories, dyeing factories, leather factories, breweries, meat processing plants, pharmaceutical factories, paper mills, coal washing, metallurgy, mining areas, etc.

6.It can be used for wrinkle resistance in leather and fabric.

7.It can be used for cement solidification and molding casting.

8.It can be used for refining pharmaceuticals, glycerol, and sugars.

9.It can serve as a good catalyst.

10.It can be used for paper bonding.

VII.Application Method: Users can determine the optimal dosage by adjusting the agent concentration through experiments according to different water qualities and terrains.

1.Liquid products can be directly applied or diluted before use. Solid products need to be dissolved and diluted before use. The amount of dilution water should be determined based on the water quality to be treated and the quantity of the product. The dilution ratio for solid products is 2-20%, and for liquid products is 5-50% (by weight).

2.The dosage of liquid products is 3-40 grams per ton, and for solid products, it is 1-15 grams per ton. The specific dosage should be based on flocculation tests and experiments.

VIII.Packaging and Storage: Solid products are packaged in 25kg bags with inner plastic film and outer plastic woven bags. The product should be stored indoors in a dry, ventilated, and cool place, away from moisture.

PAC

PAC PFS

PFS Industry News

Industry News Exhibition News

Exhibition News

Send Email

Send Email Phone

Phone